Introduction

In the heart of India’s industrial landscape, the brass hubs of Jamnagar, Moradabad, and Ahmedabad are redefining sustainable manufacturing with Jamnagar brass precision components now supplying EVs and industry worldwide. These regions transform over 1,200 tons of brass scrap daily into high-precision components for electric vehicles (EVs), aerospace, and even sacred temple bells. With a focus on circular economy principles, cutting-edge technology, and global compliance standards like RoHS and PPAP Level 3, India’s brass industry—led by innovators like Shiv Om Brass—is poised to meet the demands of US and EU markets. As the global EV components market surges toward USD 109 billion by 2030, discover how these hubs deliver quality, sustainability, and reliability for your supply chain.

1. The Circular Economy in Action

India’s brass industry thrives on a robust “waste-to-wealth” model, recycling scrap into precision parts for global industries.

1.1 Scrap Collection and Recycling

Every day, multigenerational kabadiwalas (scrap collectors) in Jamnagar, Moradabad, and Ahmedabad gather 1,200 tons of brass scrap, fueling a USD 300 million circular economy. In Jamnagar alone, this ecosystem supports over 250,000 workers, creating a vibrant supply chain for industries like automotive and electronics. Approximately 70% of the brass processed in Jamnagar’s “Brass City” comes from recycled materials, making it one of the world’s largest brass recycling hubs. The cluster consumes 8,000 tons of scrap monthly, navigating price fluctuations (from USD 6.5 to USD 5/kg) to ensure stable production for domestic and export markets.

1.2 Environmental Impact

By transitioning from traditional coal-pit furnaces to modern induction furnaces, 600 micro, small, and medium enterprises (MSMEs) in Jamnagar save 114 tons of CO₂ daily—equivalent to the annual emissions of 10,000 US households. These induction systems boost energy efficiency by 30%, reducing costs to USD 0.035–0.037/kg. This shift not only lowers the carbon footprint but also aligns with the sustainability goals of US and EU buyers, making India’s brass components a green choice for global supply chains.

2. India’s Brass Powerhouses

Each hub brings unique strengths, with Jamnagar leading as a global exporter.

2.1 Jamnagar: The Global Brass City

Jamnagar, known as India’s “Brass City,” hosts 3,500–5,000 MSMEs, including 900 foundries, 150 extrusion shops, 2,100 machining centers, and 350 electroplating units. Producing USD 3 billion annually, it accounts for 80% of India’s brass exports, shipping 25% of its output to over 100 countries, including the US and EU. Unlike decorative-focused regions, Jamnagar specializes in high-tolerance components like EV busbars, electrical connectors, and aerospace fittings. With over 400,000 jobs supported, it’s a cornerstone of both economic and industrial growth. Buyers sourcing Jamnagar brass precision components benefit from unmatched sustainability, tolerance, and compliance advantages.

2.2 Moradabad and Ahmedabad

Moradabad, another “Brass City,” contributes 20% of India’s non-ferrous recycling, with over 1,000 small foundries crafting lock components and ornamental hardware. Ahmedabad, an emerging hub, excels in precision extrusion and CNC machining, supplying ISO 9001 and RoHS-compliant parts for medical devices and data center connectors. Together, these regions complement Jamnagar’s scale with specialized expertise.

3. From Scrap to Precision Component

The journey from raw scrap to finished product is a masterclass in efficiency and quality.

3.1 Collection and Sorting

Scrap is meticulously sorted by alloy, cleaned, and crushed to achieve 99% recovery of copper, zinc, and trace metals. This ensures consistent melt quality, critical for high-precision applications.

3.2 Melting and Refining

Modern induction furnaces have replaced oil-fired pits, cutting particulate emissions by 85% and improving melt rates by 20%. These advancements ensure cleaner production and higher yields, meeting the stringent demands of global buyers.

3.3 Precision Machining and Quality Control

Using Swiss sliding-head and 5-axis CNC machines, manufacturers achieve sub-0.01 mm tolerances for components like busbars and connector blocks. Integrated X-ray and pull-out tests ensure compliance with PPAP Level 3 standards, while award-backed labs provide full chemical and mechanical traceability for audit-ready documentation.

4. Powering the EV Revolution

India’s brass industry is uniquely positioned to capitalize on the booming EV market.

4.1 India’s EV Components Market

Valued at USD 4 billion in 2024, India’s EV components sector (batteries, motors, power electronics) is projected to reach USD 17 billion by 2033 at a 17.3% CAGR. The broader market, including charging infrastructure and drivetrains, is expected to grow from USD 15.25 billion in 2023 to USD 109.34 billion by 2030 at a 32.5% CAGR, driven by global demand for sustainable mobility.

4.2 The Rise of Brass Busbars

The high-power EV busbar market, valued at USD 467.5 million in 2024, is forecast to reach USD 3.32 billion by 2034 at a 20.8% CAGR. While aluminum holds a 70% share, brass busbars are gaining traction for their superior corrosion resistance and conductivity in high-voltage applications, making them a critical niche for US and EU manufacturers.

5. Why Choose Jamnagar Brass Precision Components from India?

India’s brass industry offers unmatched advantages for US and EU buyers:

- Sustainability: 70% recycled input and 114 tons of daily CO₂ savings align with ESG goals.

- Precision: Sub-0.01 mm tolerances meet the needs of EV, aerospace, and data center applications.

- Compliance: RoHS and PPAP Level 3 certifications ensure audit-ready supply chains.

- Reliability: Duty-safe buffer stock in the US and EU guarantees on-time, in-full delivery.

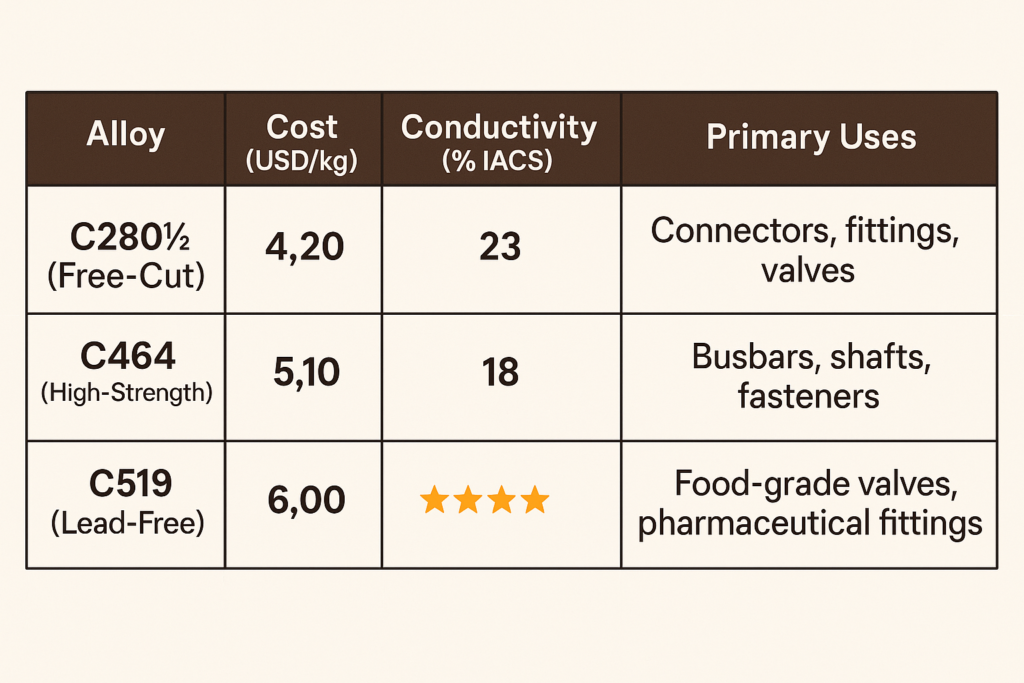

Still deciding on the right material for your EV or industrial application?

Here’s how our most in-demand brass alloys compare.

6. Strategic Insights for Buyers

- Price Stability: Brass scrap prices can fluctuate by 25% monthly, but buffer-stock strategies in key markets like Pennsylvania and New Jersey stabilize costs.

- Job Creation: The industry supports over 650,000 jobs, resonating with corporate social responsibility goals.

- Energy Savings: Full adoption of induction furnaces could save USD 36 million annually in fuel costs, enhancing cost-competitiveness.

7. Partner with Shiv Om Brass

Partner with Shiv Om Brass

Based in Jamnagar, India’s brass manufacturing hub, Shiv Om Brass produces high-precision, RoHS-compliant components with advanced CNC capabilities. Our parts serve applications from electrical and HVAC systems to automotive assemblies. With ISO 9001 quality management, sustainable sourcing, and proven export expertise to over several countries, we deliver consistent quality with on-time, corridor-optimized shipping.

Take the Next Step:

- 📧 Contact us at yash@shivombrass.co.in to discuss your project.

- 📦 Request a custom PPAP Level 3 package tailored to your needs.

- 🚚 Benefit from on-time, duty-safe delivery to the US and EU.

Join the Circular Economy Revolution: Partner with Shiv Om Brass to drive sustainability and precision in your supply chain.

References

United Nations Industrial Development Organization. (n.d.). Decarbonization in Industry. Retrieved from https://decarbonization.unido.org

SAMEEKSHA. (n.d.). Energy Efficiency in MSMEs. Retrieved from http://www.sameeksha.org

The Financial Express. (n.d.). Brass Scrap Price Trends. Retrieved from https://www.financialexpress.com

IMARC Group. (2024). India Electric Vehicle Components Market. Retrieved from https://www.imarcgroup.com

Global Market Insights Inc. (2024). Electric Vehicle Busbar Market. Retrieved from https://www.gminsights.com